Gas detection is an important safety precaution in the utilities industry. However, when it comes to using gas detectors for utility work, it’s often hard to know how you should configure it for your specific application. Case in point: working in the utilities industry could include digging trenches, working in manholes, installing/repairing cables, monitoring power distribution, and so on. All these examples (and more) require gas detection, and in these few examples alone, the way you use and configure your gas monitor can vary dramatically.

But the stakes couldn’t be higher. The utilities industry is one where we see too many preventable deaths, if only the worker had the right equipment and used it correctly.

So how do you make it easier for workers to stay safe with gas detectors? Build a gas detection program based on smart gas monitors that can multi-task.

Consider power distribution and manholes. If you often work in this area, you know summer can sometimes be a bummer. When outside temperatures exceed 100 degrees Fahrenheit for days on end, there tend to be power outages related to the heat. The heat causes equipment to malfunction and may even spark fires. When this happens, utility workers not only have to deal with the danger of high temperatures, but they must also enter manholes or underground vaults that could contain gas hazards to repair the faulty equipment—and fast.

This can be a recipe for disaster because when you’re in a hurry, safety isn’t always top of mind. Not only do you need to worry about the gases that could have built up in this confined space prior to entry, but you also need to think about the gases that could be released from the faulty equipment.

Depending on the situation, workers may find themselves repairing equipment in an environment that has high concentrations of different gases, often carbon monoxide. If carbon monoxide (or any other gas) levels are high enough, this would require the individuals to wear SCBAs to ensure that they can complete their job without putting themselves at risk of carbon monoxide poisoning.

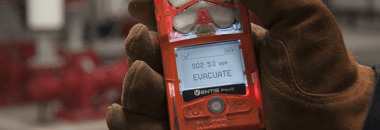

For confined spaces like manholes or underground vaults, you should use an aspirated (pumped) gas detector to conduct pre-entry screening of the atmosphere. Depending on the gas concentrations in the atmosphere, you may also need to use additional PPE, like an SCBA, to conduct the work. Gas detectors that offer custom alarm messages can make this decision easy by displaying a message like “Wear SCBA” when gas hazards require additional precautions.

In cases where urgent utility work needs to be performed with PPE and known elevated gas levels are present, gas detection becomes more complicated. In a situation like this, the gas monitor will be in alarm and the worker will ignore the gas readings, audible alarms, and visual indicators on the monitor because they already know that the gas is present. This is when alarm fatigue sets in. The risk here is that workers are no longer paying attention to the gas monitor, so they could very likely miss important alarm notifications for combustible gases. You can easily prevent this dangerous situation with a gas monitor with acknowledgeable alarms. You can program the monitor so that workers can acknowledge an alarm for one gas and still receive alerts if conditions change. If another gas hazard rises to a concerning level, the monitor will alert them accordingly.

When there is a significant impact to the general population, workers can sometimes find themselves in unsafe territory, but gas detectors with custom alarm action messages and acknowledgeable alerts can help workers make the safest decisions possible.