Several years ago, a plant-wide power outage in Texas forced a plant to flare off product, including sulfur dioxide (SO2). As the toxic black smoke drifted into nearby communities, safety officials partially shut down the area and issued a precautionary shelter-in-place alert to protect residents.

Meanwhile, just weeks ago, a train carrying five rail cars worth of vinyl chloride derailed in Ohio. Each car was unstable and could potentially explode, causing a deadly disbursement of shrapnel and toxic fumes, according to the office of Ohio Gov. Mike DeWine. Like the plant in Texas, there was a controlled release of chemicals – but this time, residents had to be fully evacuated to ensure their safety.

While these incidents vary in location and impact, both incidents remind us that events beyond our control can and will happen – and that’s why it’s so critical to be prepared for potential emergencies, however unlikely they may seem.

During an unplanned chemical release, there will be more questions than answers. Safety managers may ask things like: What’s happening on the ground? What gas is being released? How much was released and where is it going? Could this chemical release spark a fire? Will employees, responders, and community members be exposed to dangerous levels of gas? When will that happen? Is it safe to shelter-in-place or should residents evacuate? When will the area be considered safe?

After recent events in Ohio, however, you should be asking yourself: “If this happened to us right now, how would we respond?”

Having an operational readiness model in place is the best way to answer these questions and more. Read on to learn how you can apply an operational readiness model on your worksite.

What is an Operational Readiness Model?

In short, an operational readiness model is a workplace solution that gives you the ability to prepare for the worst-case scenarios while optimizing your response plans and day-to-day operations so that you can protect not only your assets, but your people on the ground and the surrounding community.

An operational readiness model also means there’s a common operating picture for everyone. Equipped with a common operating picture, you and your teams can make quick and well-informed decisions to mitigate impact, get back to work faster, and much more.

Preparing for a Chemical Emergency

Every good operational readiness model should include a chemical emergency toolkit. A chemical emergency toolkit provides a common operating framework during a variety of emergencies that helps you rapidly respond to incidents, limit financial loss, understand environmental impact, and protect human health.

Including local communities in an operational readiness plan is crucial. By outlining communication plans and training the community and staff on sheltering-in-place and other protective measures, safety managers can assure community members that a facility is ready to handle emergencies quickly and confidently to protect nearby residents.

So what else should you include to protect your people, plant, and community during a chemical emergency?

1. Personal Gas Monitors

The first line of defense against gas hazards, particularly ones that could spark a fire or worse, is a small personal monitor. While personal gas monitors are essential and critical in protecting individual personnel, a true emergency response plan requires careful consideration of how these tools can be used in a broader context.

2. Area Monitors

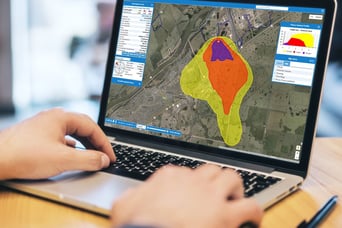

Adding connected area monitoring equipment, for example, greatly improves multi-threat detection, establishes hazard perimeters, monitors for long-term hazards, enables remote monitoring of potential critical receptors, and is easy to move as an emergency event unfolds. Plus, connected area monitoring equipment can be further enhanced with real-time weather data and dynamic plume modeling software like SAFER One® to predict the path of airborne hazards, allowing you to truly take control of any emergency.

3. Real-Time Weather Data

Incorporating real-time weather data in an operational readiness plan and chemical emergency toolkit helps increase the scope of a facility’s ability to respond. Conditions can change rapidly during a crisis and relying on outdated data can prevent you from making the safest decision.

By understanding ever-changing weather conditions surrounding a site, you can pinpoint areas of concern, such as where a fire or gas hazard may spread and ensure the safety of nearby residents. No matter the hazard, real-time weather data determined by plume modeling helps you determine where to deploy team members in an emergency.

How to Use an Operational Readiness Plan to Reduce Daily Risks

To get the most value out of your operational readiness plan and tools, use them for day-to-day operations as well. When you run plume models and prepare for planned events that may be risky, you take safety plans from reactive to proactive to prevent exposure and reportable incidents.

For example, if your facility is planning a turnaround, you might run models to understand which areas of the site are more likely to be impacted by a leak that could spark into a larger explosion or fire.

With this information, you can strategically place area monitors around the perimeter to alert you if the gas plume extends beyond the expected boundaries. If something goes wrong, you are already prepared and can avoid sending workers into the gas plume to set up gas monitors.

By combining your toolkit and operational readiness plans with emergency drills, you can take control of any situation to protect your workers, community, and environment. For example, safety managers can review emission sources, chemical data, pre-defined worst-case scenarios, and more to say, “if this chemical tank explodes today, what will happen?” With one click, safety personnel can factor in real-time weather data and see what the true “worst-case scenario” is in that moment, if and where a fire could occur, if a chain reaction is possible, and much more.

By using these real-time tools, you can take the guesswork out of planning for and responding to a chemical release, allowing you to partner with first responders to make safe decisions with confidence, both inside your facility and in the communities surrounding it.

To learn more about creating operational readiness models with SAFER One®, download our eBook: How to Use Dynamic Plume Modeling for Safer Worksites and Communities.