Gas detector calibration is a critical aspect of maintaining your gas monitors. Gas detectors can be difficult to maintain, especially when you need to perform frequent calibration. Gas detector calibration procedures are not particularly challenging or time-consuming. They only require a few minutes and a few button presses.

In fact, the tough part is finding the time in your schedule when countless other tasks demand your attention. As your days get busier, it gets harder to find the time to stop and maintain something that may not be showing visible signs of wear and won’t help you finish your job faster.

However, when you neglect routine maintenance on your direct-reading gas monitors, you risk exposure to dangerous hazards—like toxic gases, oxygen deficiency, or combustible gases—that can cause significant injuries or even death.

The Importance of Routine Gas Detector Calibration

It’s important to maintain your gas monitor so you know that it will protect you as expected. You have a particular skillset that allows you to perform your job—make sure to maintain your gas detector so it can do its job, too.

Device manufacturers typically recommend bump testing before each day’s use and monthly calibrations to ensure your gas monitor performs at its best.

How Often Should You Calibrate Your Gas Monitor?

Unfortunately for the industry, there is a dangerous rumor that industry-standard maintenance recommendations are unnecessary and manufacturer recommendations are just a ploy to sell calibration gas.

The popularity of these rumors has spiked in recent years with the introduction of multi-gas monitors with new low-power, infrared sensor technology for combustible gas detection that claim to perform for up to two years without needing to be calibrated.

These low-power infrared sensors deliver on their claim of extended instrument runtime, but these gas monitors use the same electrochemical sensor technology for toxic gas detection. Because the technology is the same, calibration is still just as important, and the maintenance recommendations should remain the same. For example, if you install a new car stereo, you should continue to rotate your tires regularly.

The Effect of Sensor Drift

Instrument manufacturers’ calibration recommendations are based upon many factors, one main reason being sensor drift. Sensor drift is the natural tendency of a sensor’s performance to degrade over time as its components age. This is an undeniable fact for electrochemical sensor technology.

In September 2013, OSHA published a Safety and Health Information Bulletin titled “Calibrating and Testing Direct-Reading Portable Gas Monitors.” In this bulletin, OSHA identified nine factors that contribute to sensor drift. Seven of these factors relate to electrochemical sensors:

- Degradation of phosphorus-containing components

- Degradation of lead-containing components

- Gradual chemical degradation of sensors and drift in electronic components that occur normally over time

- Use in extreme environmental conditions, such as high/low temperature and humidity, and high levels of airborne particulates

- Exposure to high concentrations of the target gases and vapors

- Exposure of electrochemical toxic gas sensors to solvent vapors and highly corrosive gases

- Handling/jostling of the equipment causing enough vibration or shock over time to affect electronic components and circuitry

The third factor, sensor drift, is typically defined by sensor manufacturers as a <2% to <5% shift in sensor readings per month. In other words, a sensor that detected 100ppm immediately after calibration may read as low as 95ppm after one month while ignoring the impact of other environmental factors. Sensor specifications are based on laboratory testing; however, they will perform worse than specification if they’re constantly subjected to challenging applications and environments.

Sensor drift is inevitable and happens to all sensors over time. Regular calibration is the only way to verify your gas monitor’s reference point for gas readings. Unfortunately, there’s no avoiding it.

Example of Sensor Drift

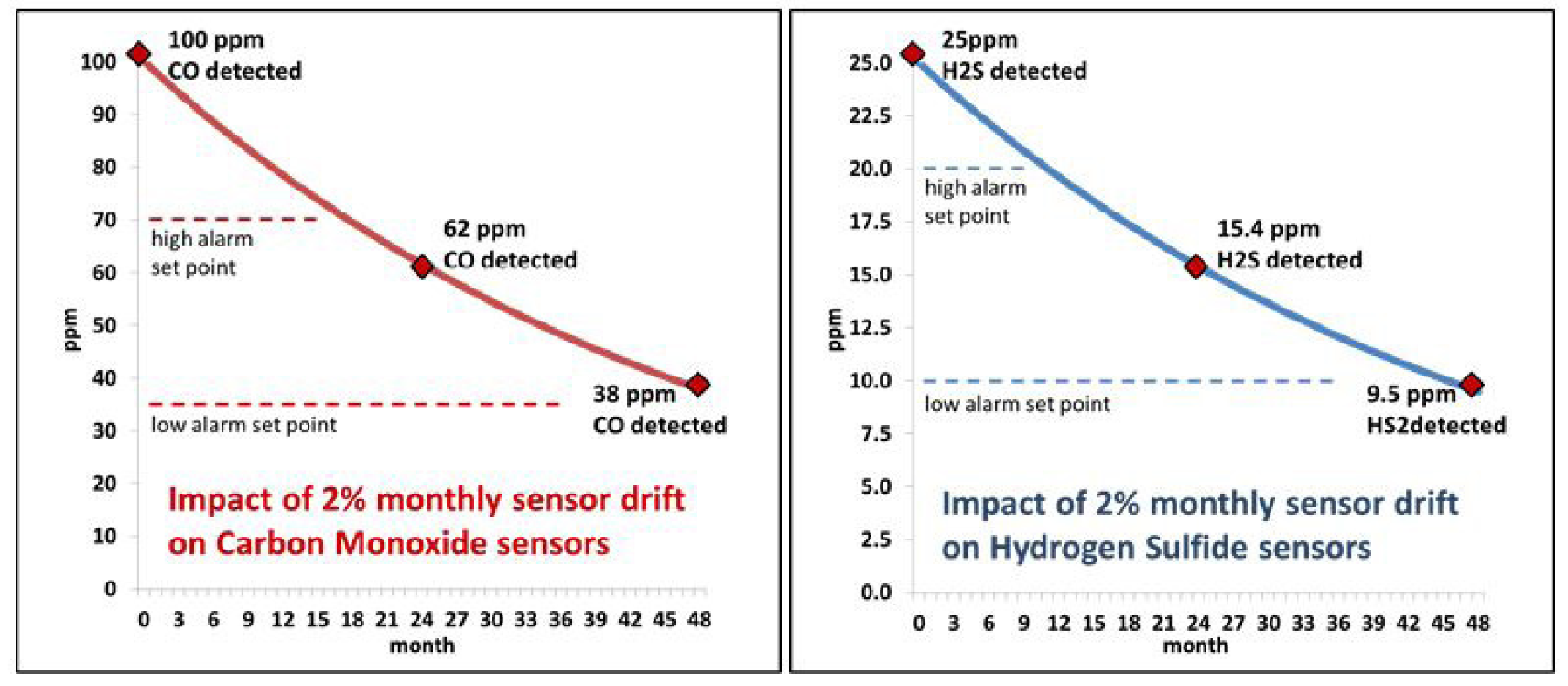

For simplicity’s sake, the following example will ignore all other causes of sensor drift (including the other seven factors listed above, as well as temporary drift caused by sudden changes in temperature and humidity). The two graphs below assume a 2% monthly sensor drift for carbon monoxide (CO) and hydrogen sulfide (H2S) sensors and standard calibration concentrations of 100ppm and 25ppm, respectively.

The compounding effect of a 2% monthly sensor drift alone results in 38% lower readings after 24 months and 62% lower readings after 48 months. In other words, after two years, an instrument in a hazardous environment exposed to 100ppm of CO and 25ppm H2S could display 62ppm of CO and 15.4ppm of H2S.

After four years, the readings would be 38ppm of CO and 9.5 ppm of H2S. Again, these graphs ignore all other potential causes of instrument inaccuracy except for natural sensor drift. After four years, assuming standard alarm set points, neither gas monitor would produce a high alarm. The H2S reading wouldn’t even trigger a low alarm.

Bump Tests vs Gas Calibration

One common argument against the need for routine calibration is using a periodic bump test to validate sensor performance. A bump test is designed to ensure the gas monitor will detect the presence of a gas, not to validate the accuracy of the measurement. A common standard to pass a bump test is the instrument must detect 50% of the calibration gas concentration exposed to the gas detector.

In these examples, the gas monitor would be required to detect 50ppm of CO and 17.5ppm of H2S. Only after 34 months of gradual sensor drift the instruments would fail a bump test. Bump tests are incredibly important tools, but never should be considered as an alternative to instrument calibrations.

For example, let’s say your coworker borrowed your brand-new gas detector yesterday for a few hours. On his way back to the office, he accidentally dropped it in the mud, which clogged the sensor openings. If you bump test the instrument before your next use, the bump test will catch the problem and fail, as the gas will not reach the sensors. It will not adjust the measurement accuracy in any way, only test the ability of gas to reach the sensor.

How to Calibrate a Gas Monitor

If your site has a small gas monitor fleet, manual maintenance may be a good option. You can perform manual calibrations using tubing and a cylinder of calibration gas.

Another way to ensure proper gas monitor performance and reduce maintenance hassles is to use a docking station or calibration station. These devices are a great option for large fleets because they automate your routine bump tests and calibrations. Plus, they automatically download datalogs, update settings and firmware, and, most importantly, allow you to focus on your job.

Gas Detector Calibration Tips

Expose the Sensors to the Right Gas

When calibrating your gas monitor, it is essential to expose the sensors to the right gas to get an accurate calibration. Using incorrect or expired calibration gas can lead to an improper calibration, meaning your gas detector won’t display accurate readings. This simple mistake can have life-altering consequences, so always check the contents and expiration date of your calibration gas bottles. Once a bottle is expired, you should not use it because chemical reactions can take place inside the container and alter the contents.

Use An Environment Similar to Your Working Conditions

The environment, including temperature, pressure, and humidity, can also impact calibration and gas readings. Make sure to calibrate your gas monitors in an environment similar to your working conditions for best results.

FAQs about Gas Detector Calibration

What's the difference between calibration and bump testing?

Calibration ensures the accuracy of a gas detector by adjusting its response to a known gas concentration. Bump testing, on the other hand, is a quick check to ensure the device responds to a gas concentration but doesn't adjust its accuracy. In a bump test, the instrument is exposed to a known concentration of gas, and the response is observed without making any adjustments. While bump tests are faster and can be done more frequently, they don't replace the need for regular calibrations.

Can I use any calibration gas for my gas detector?

No, it's essential to use the specific calibration gas recommended by the manufacturer. Using an incorrect or impure calibration gas can result in inaccurate measurements and compromise the safety of the device's operation. Always ensure that the calibration gas concentration, blend, and balance gases match the requirements specified by the gas detector's manufacturer.

Conclusion

While no one will argue that frequent instrument calibration isn’t a hassle, its importance should never be minimized. The examples above described how an improperly calibrated gas detector could lead to wildly inaccurate readings over time. Gas detectors are life saving devices. Don’t let misleading information or a few minutes of maintenance get in the way of having the tools you need to complete your job safely.

To learn more about your maintenance options, download our eBook, Take the Pain out of Gas Detector Maintenance or talk to one of our experts today.