As winter approaches, ensuring the reliability of your gas detection equipment in harsh conditions is paramount for outdoor workers. Cold weather can significantly impact the performance of gas monitors, introducing potential safety hazards that must be addressed.

By following some simple tips, workers and safety managers can worry less about a portable gas monitor’s performance and trust it more to prevent exposure to toxic or combustible gases.

Temperature Thresholds

When working in cold weather, consider the minimum temperature gas monitors in your fleet can tolerate. While some instruments are rated as low as -40 degrees Celsius or -40 degrees Fahrenheit, most portable gas monitors have a low temperature rating for continuous operation at -20 C or -4 F. Even so, most instruments may only be used at lower temperatures for short periods.

Regardless of the rating, try to limit exposure to extreme temperatures as much as possible. Consult the gas monitor’s specification sheet to find its suggested temperature range.

Gas Reading Accuracy

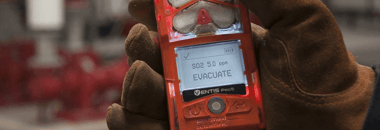

Accuracy from gas monitors is crucial for responding appropriately to atmospheric changes. In the presence of toxic or combustible gases, an accurate reading from a gas detector can mean the difference between life and death by providing time to escape an unsafe environment.

Does temperate play a role in the readings obtained from gas detectors? Sensor response will certainly change as temperatures get colder, but more sophisticated gas monitors typically use "temperature compensation" to keep gas readings within +/-15% of the actual concentrations. All Industrial Scientific gas monitors feature temperature compensation, allowing users to rely on the readings from their gas detectors to inform their next steps.

While many aspects of cold weather gas detection are uncontrollable, a few easy actions can help stay protected and maintain the health of devices in frigid conditions.

Maintenance Needs

Atypical weather conditions call for specific maintenance needs to help extend the life and performance of a gas detector fleet:

- Store gas monitoring equipment in a humid area. Cold winter climates can be extremely dry, especially in regions like the Northern Plains, Northwest Canada, and Alaska. This dry climate impacts the performance of some electrochemical sensors even more than cold temperatures. To prevent the aqueous electrolytes from drying out, store and charge instruments in a humidified area. Keeping the ambient relative humidity at 40-50% will significantly help maintain the sensitivity of sensors and prolong their working life.

- If a gas monitor is lagging, perform more bump tests. The response of the instrument may appear sluggish at temperatures below -20 C. The display may dim and even go blank if it freezes. In such cases, the gas monitor will likely still detect gas and alarm. If used in this way, it is important to bump test the instrument before each use to ensure it responds, and to warm up the instrument as soon as possible.

- After working out in the cold or if the gas monitor’s readings may not be reliable, check the oxygen sensor to ensure it is not frozen. The electrochemical sensors in the instrument typically have an aqueous electrolyte, which may freeze as temperatures drop below -20 C for extended periods. The oxygen sensor is usually the first to freeze. When frozen, the sensors will not produce a reliable reading, but should return to typical functionality once they warm up and thaw out.

- Be prepared to charge gas monitors more frequently in the winter. Battery run time may be reduced in cold temperatures; below -20 C, run time may be reduced by 50% or more.

In the Field

Compliant precautions and proper behavior when using a gas monitor out in the field can significantly improve its performance.

If the duration in the cold is less than 20 minutes, there is no need to stabilize the gas monitor and adjust to the outdoor temperature before use. However, if the monitor will be used outside for more than 20 minutes, be sure to allow it to adjust to the cold before use. It will take some time for it to reach equilibrium with the ambient temperature, about 15-20 minutes, then turn it on and zero the sensors in the fresh air.

Finally, keep the gas monitor warm until needed. This can be done by keeping the gas monitor close to the body until it is ready for use. If using the monitor for remote sampling, keeping it inside a coat until it is time to read the screen will help maintain its warmth and functionality.

A good rule of thumb for using gas detectors in cold weather is that if it is bearable to work in the cold, the gas monitor can also function. If it’s too cold for the worker, it’s probably too cold for the instrument.

Don’t let the season leave gas detectors out in the cold. Stay safe and warm this winter season.