As a safety professional, you likely already know that confined spaces pose many challenges to team safety. Despite awareness, regulation, and technological advancements, confined space injuries and fatalities continue to occur. According to the National Safety Council, in a 2020 survey 13% of workers reported that a confined space entry had caused or contributed to a serious workplace injury at their facility.

What steps can you take to minimize the danger for your workers?

Hazards of Working in Confined Spaces

Confined spaces are not designed for continuous human use. However, they are large enough to enter and work in when a task demands it. Because these spaces aren’t created with people in mind, they have restricted entry and exit paths and may have unique risks—like atmospheric hazards or walls that could trap or asphyxiate an entrant—that categorize them as permit-required confined spaces.

Along with the hazards inherent to the space itself, lack of ventilation increases the risks of atmospheric hazards in confined spaces. The top four atmospheric concerns for workers are oxygen deficiency, oxygen enrichment, combustible gases, and toxic gases.

Let’s review some key ways to manage the risks of confined spaces then examine a common scenario a worker could face while entering one to see the techniques in action.

Creating a Confined Space Entry Plan

A well-rounded confined space entry plan—including setting up the right confined space monitor—is critical to minimize risk.

As with many responsibilities, planning ahead for confined spaces can help prevent unnecessary incidents and reduce the risk of injury or death. No two confined spaces are the same, so prior to entry it is essential to examine each space for risk and hazard assessments, choose the right confined space monitor, and train workers.

Confined Space Testing Best Practices

Regulations generally require testing the atmosphere within a confined space with a direct-reading monitor before a person enters. This is commonly performed with a confined space monitor equipped with a remote sampling pump and allows the user to see not only if the space is safe, but also how safe.

Although testing after that is only required before re-entry, it’s safest to continuously monitor for atmospheric hazards because conditions can change within moments, leaving workers unaware of danger. Area monitors are helpful for continuous monitoring because of their long battery life and easy set-up—simply turn the monitor on and place it in the confined space to ensure that you always have visibility into the gas readings.

Quickly Communicate Working Conditions

Communication is a major factor in protecting workers in confined spaces. Attendants are required to monitor the areas and the status of the workers within them. However, because of ever-changing conditions and loud environments it can be a challenge for attendants and peers to understand the status of entrants.

With connected gas monitors, alarms for gas hazards, immobility, or other safety emergencies are instantly shared to peers and the attendant, enabling a quick and effective response.

Confined Space Safety Plan in Action

Confined Space Safety Plan in Action

Let’s walk through a specific scene where a crew avoids hazardous atmosphere exposure while working in a confined space to understand how to apply these principles.

Jason is about to re-enter a confined space after taking a lunch break. He's in a hurry to finish work so he can keep the project on time and on budget. However, just before his crew left for their break, someone accidentally left a valve on an argon hose open. Since then, argon gas has filled the space, slowly displacing oxygen.

By the time the crew is ready to resume work, argon has displaced oxygen well below proper levels, putting workers at risk for health issues or even death.

Fortunately for Jason, his facility monitors continuously for gas hazards in the space they’re working in and detects the decrease in oxygen before anyone enters.

Before Jason gets near the work zone after his break, the site’s Industrial Scientific confined space monitoring equipment automatically springs into action by alerting the entire team of the hazardous condition.

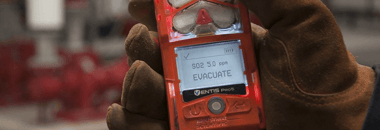

At Jason’s site, Radius BZ1 area monitors inside and outside of the confined space relay the gas readings to nearby Ventis Pro5 personal monitors and other Radius BZ1 area monitors.

Everyone on the team is notified of the hazardous gas in real time and can see which specific monitor is in alarm—enabling them to take appropriate actions and avoid the would-be rescuer tragedy stories that are all-too common in confined spaces.

Because the safety management team created an entry plan, followed testing best practices, and used connected monitors for wireless communication, they drastically increased site safety by establishing visibility into gas hazards, man-down scenarios, and panic alarms within these notoriously dangerous spaces.

Not only that, but the crew saved hours by reducing the need for manual reentry testing, resulting in projects getting done on time without sacrificing safety.

For additional information on confined space entry best practices, download our guide for detecting gas hazards in confined spaces.